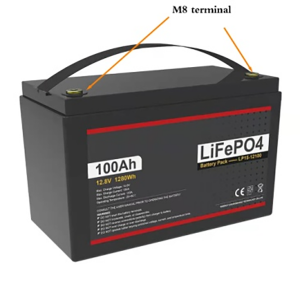

Wholesale lifepo4 battery 12.8V replace lead acid battery, the most popular lithium battery pack,LFP12.8V100AH Lithium Iron Phosphate long life cycle Battery

All energy storage field, CCTV system

Caravan; Marine ;Golf Car; Buggies; Solar Storage; Remote Monitoring; Switching applications and more

Each step have QC engineer following :

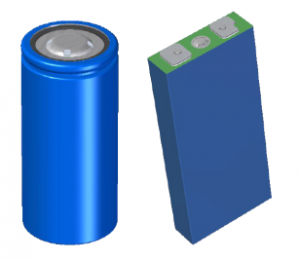

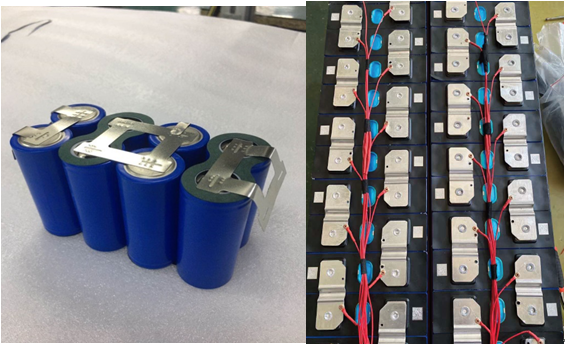

1. Choose the right battery cells, for different request and dimension, we could select the right battery cells, cylindrical cells or prismatic cells, mainly LiFePO4 cells. Only newly A grade cells used.

2.Grouping the battery with the same capacity and SOC, ensure battery packs have good performance.

3.select the right thickness nickel for working current ,welding the cells at the right way.

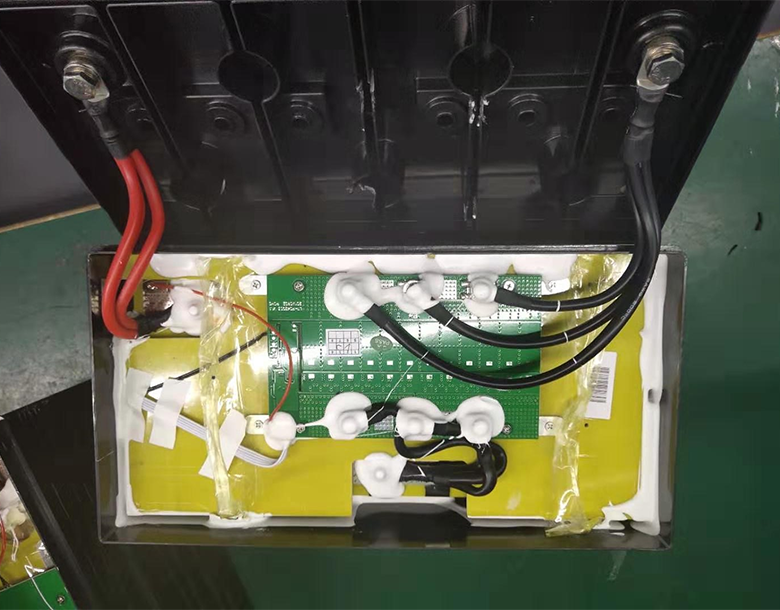

4.BMS assembly, assemble the right BMS to the battery packs.

5.LiFePO4 battery packs put into the lead Acid Case before testing

6.Semi-finished product testing and grading

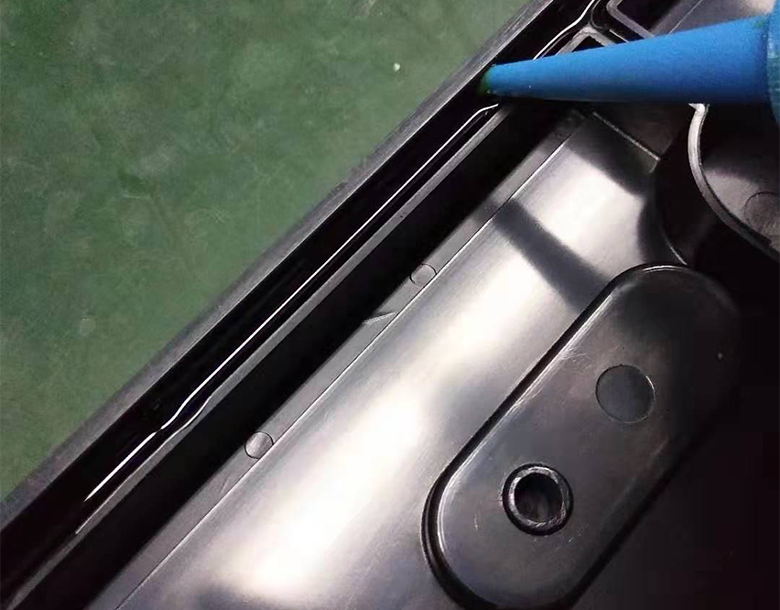

7.Good product glue seal and QC

8.Pallet Packing

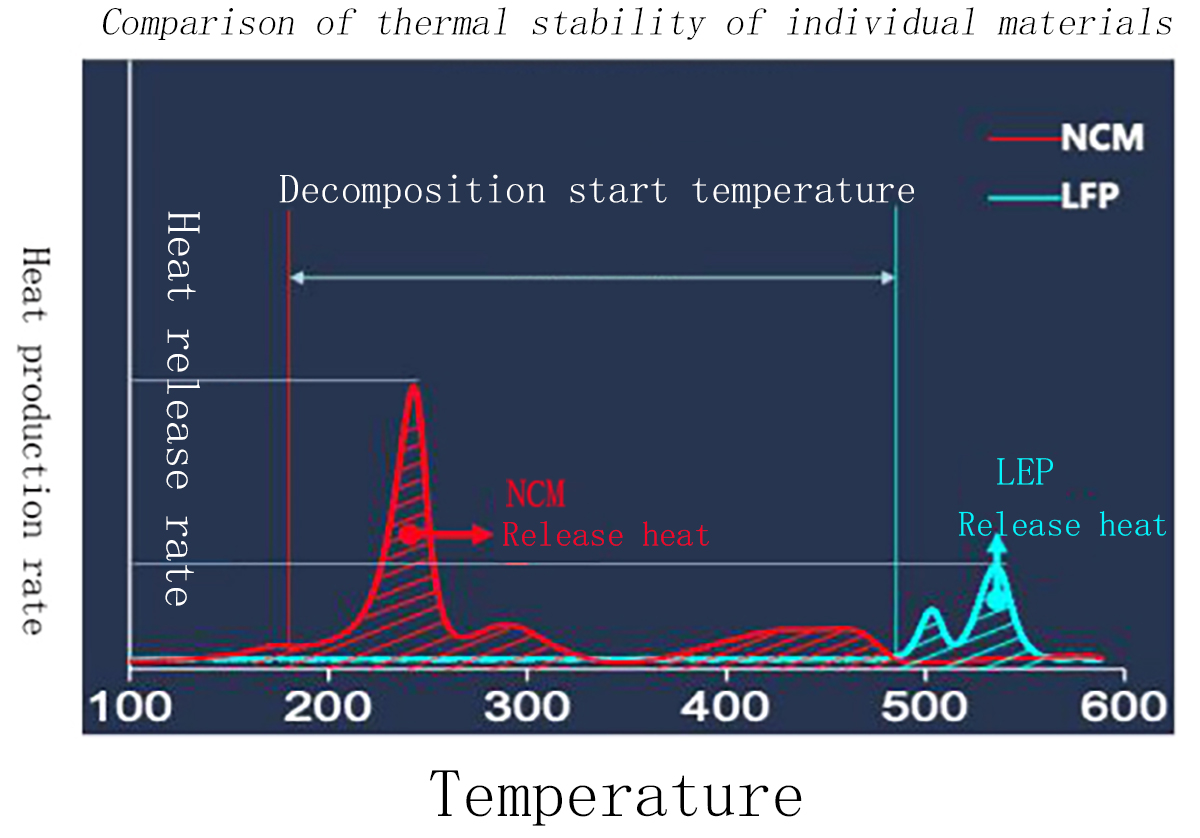

◆ Safety, Using the technology of lithium iron phosphate cell, superior safety,Long life thousands of cycles, 100%DOD, under normal conditions.

◆ Built-in automatic protection board for over-charge, over discharge, over current and over temperature.

◆ Maintenance free.

◆ Internal cell balancing.

◆ Lighter weight: About 40% of the weight of a comparable lead acid battery.

◆Standard case product and easy installed.

◆Batteries Could be series connect for higher voltage upto 51.2V system.

Wholesale Price China Lithium Battery, LiFePO4 Battery, With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept, the company will continue to develop products with high added values and continuously improve products, and will provide many customers with the best products and services!

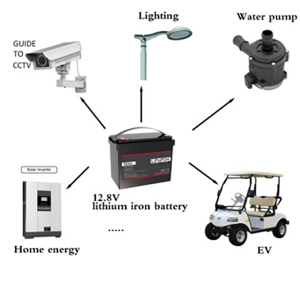

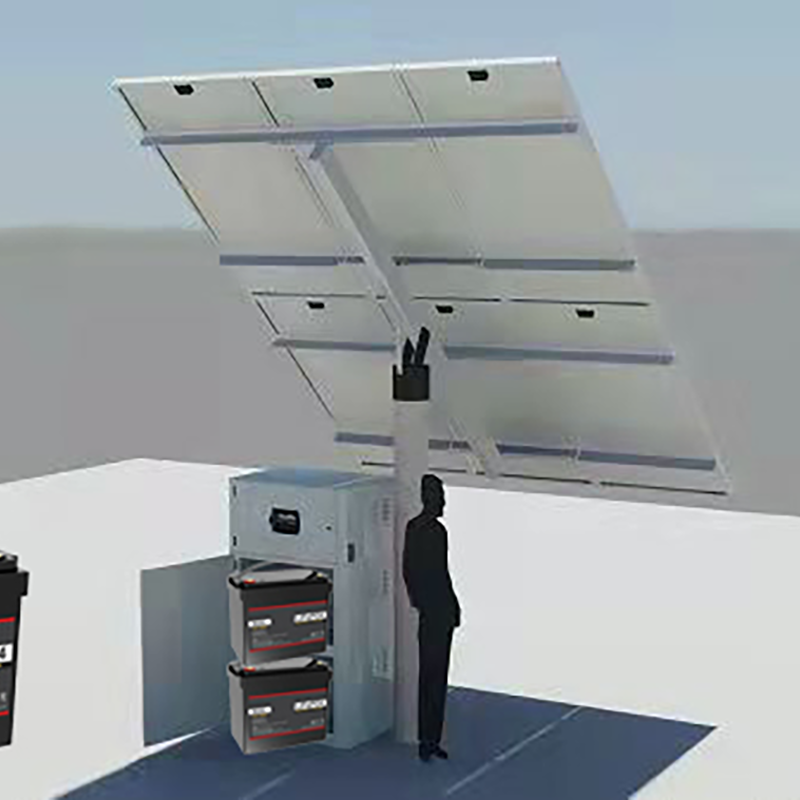

LFP12.8V Lithium ion battery Application

1.For old lead Acid battery EOL, the lithium battery could be series connect for home energy storage

2.Application for lighting

3.Golf cart power supply

4.EV board

5.Energy storage backup

6.Camera CCTV power backup

7.Others battery backup request.

back up battery for solar cctv

Golf cart power supply

Solar energy storage

ELECTRICAL PERFORMANCE

| Model/Spec. | LFP12.8V100AH-100 |

| Nominal Voltage | 12.8V |

| Nominal Capacity | 100Ah |

| Capacity @ 0.2C | 300 min |

| Energy | 1280Wh |

| Resistance | ≤30 mΩ @ 50% SOC |

| Self Discharge | <3% / Month |

CHARGE PERFORMANCE

| Recommended Charge Current | 20A |

| Maximum Charge Current | 100A |

| Recommended Charge Voltage | 14.6V |

| BMS Charge Cut-Off Voltage | <15.6 V (3.9V/Cell) |

| Reconnect Voltage | >14.4 V (3.6V/Cell) |

| Balancing Voltage | <14.4 V (3.6V/Cell) |

| Maximum Batteries in Series | 4 (*Consult IHT) |

DISCHARGE PERFORMANCE

| Maximum Continuous Discharge Current | 100 A |

| Peak Discharge Current | 200 A (3s) |

| BMS Discharge Cut-Off Current | 300 A ±10 A (30ms) |

| Recommended Low Voltage Disconnect | 11 V (2.75V/Cell) |

| BMS Discharge Cut-Off Voltage | >8.0 V (2s) (2.0V/Cell) |

| Reconnect Voltage | >10.0 V (2.5V/Cell) |

| Short Circuit Protection | 250 ~ 500 μs |

COMPLIANCE

| Certifications | CE (battery) UN38.3 (battery) |

| UL1642 & IEC62133 (cells) | |

| Shipping Classification | UN 3480, CLASS 9 |

MECHANICAL PERFORMANCE

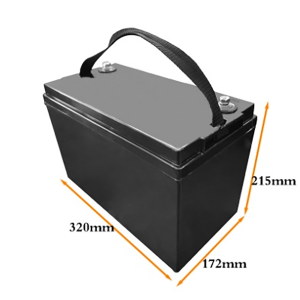

| Dimension (L x W x H) | 320 x 172 x 215 mm 13.0 x 6.7 x 8.5″ |

| Approx. Weight | 27.8 lbs (13kg) |

| Terminal Type | DIN POST |

| Terminal Torque | 80 ~ 100 in-lbs (9 ~ 11 N-m) |

| Case Material | ABS+PC |

| Enclosure Protection | IP65 |

TEMPERATURE PERFORMANCE

| Discharge Temperature | -4 ~ 131 ºF (-20 ~ 55 ºC) |

| Charge Temperature | -4 ~ 113 ºF (0 ~ 45 ºC) |

| Storage Temperature | 23 ~ 95 ºF (-5 ~ 35 ºC) |

| BMS High Temperature Cut-Off | 149 ºF (65 ºC) |

| Reconnect Temperature | 131 ºF (55 ºC) |

HEATING FOIL PERFORMANCE(Option)

| Heating Temperature Range | -4 to 41 ºF (-20 to 5 ºC) |

| Heating Time | Approximately 1 hour @ 7.5 A |

| BMS Heating Foil Cut-Off | 158 ºF (70 ºC) |

*** Note: As products are constantly updated, please contact us for latest specifications. ***

Products categories

-

Phone

-

E-mail